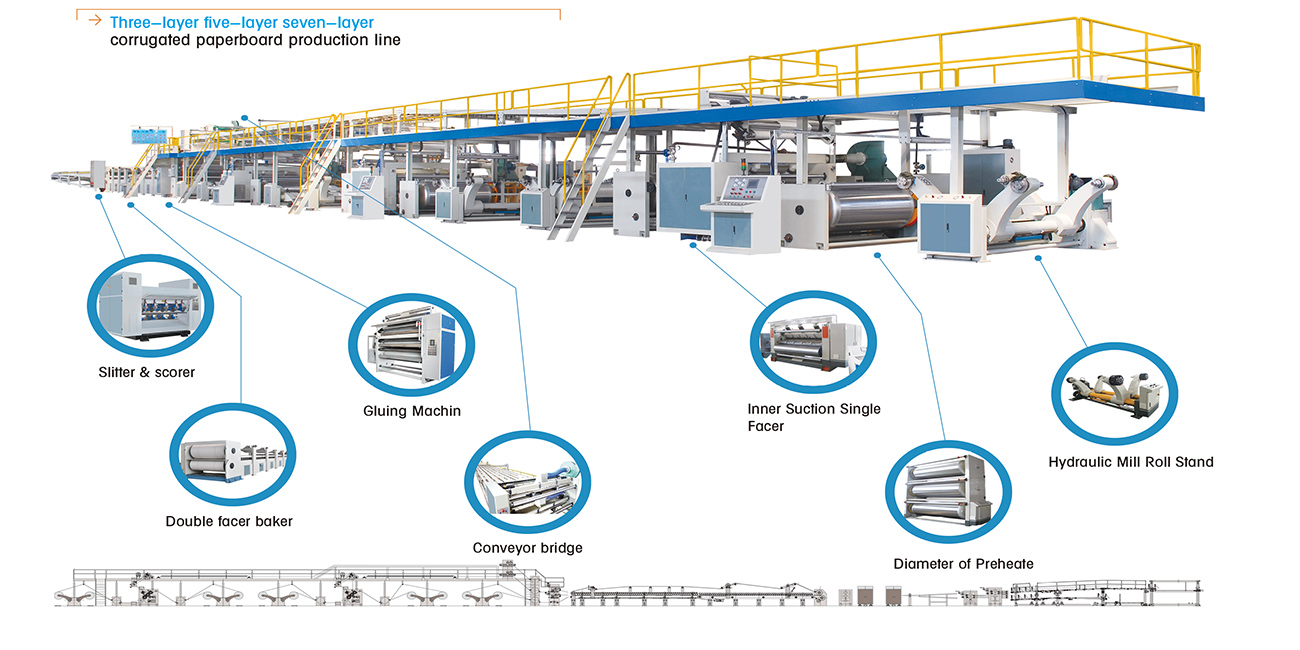

Product Description

2/3/5/7

Ply Corrugated Cardboard Production Line

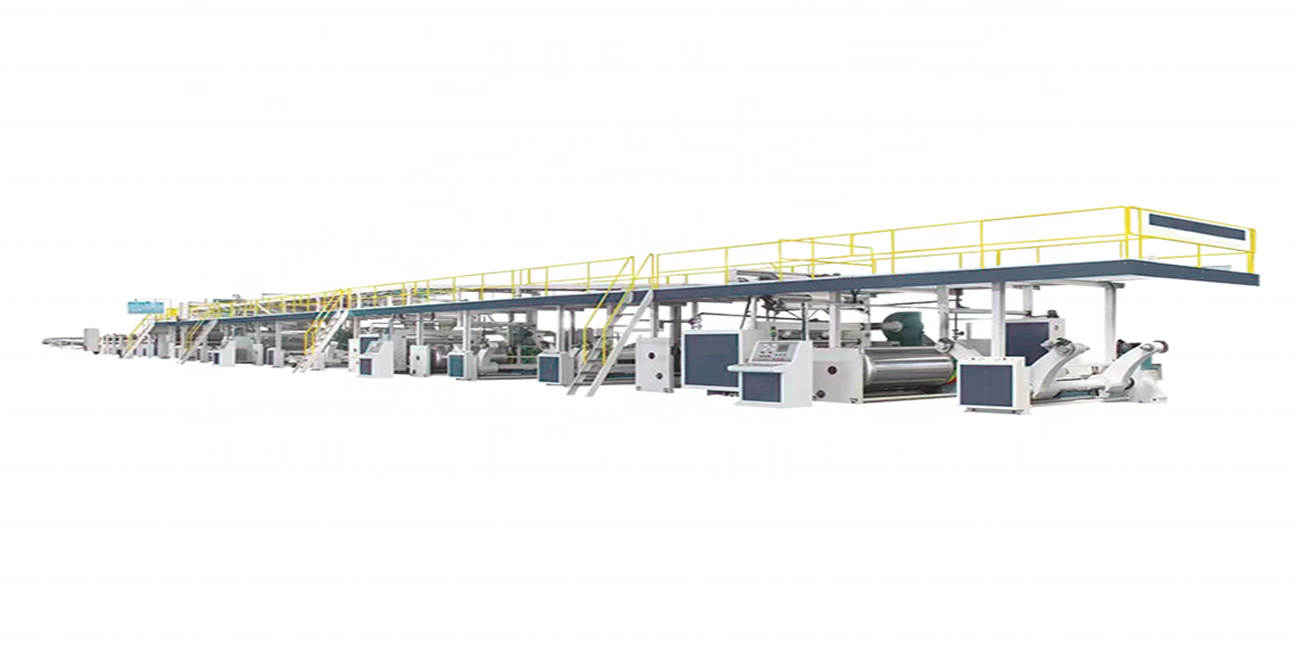

Use and Characteristics:

This production line is available in large amount automatic production, which can produce corrugated paperboard correspond to national standard with high quality, and

adopted concentrated control, operated and repaired easily, safely, reliable, reducing manpower, This production line adopts international energy saving technology with

oil heating,which can saving 40 percents energy than steam heating,So this can reduce costs effectively. lt's an economical production in big, middle paperboard

company 1. Total Length: 50-100 m 2. Total Power: 100-200 kw 3. Two option for electric mill roll stand and hydraulic mill roll stand 4. Corrugated paperboard marching:

diameter of corrugated rouer: 280-405 mm, electric adjust speed moter used

5. Double cylinder gum mounting machine: On the adoption, inside two layers draw the gun, descend to carry the paper lead the paper roller. 6. Oven: total length 7.8 m,

combined with 9-18 heating flocks. 7. Setting Part: total length 3.8-5 m, combined weith some pairs of symmetrical shafts.

8. Horizontal, Lengthuays slicing machine: Common knife or superthin knife selected based on customers demand,high automatiealy, handy operating.

Product

Desplay

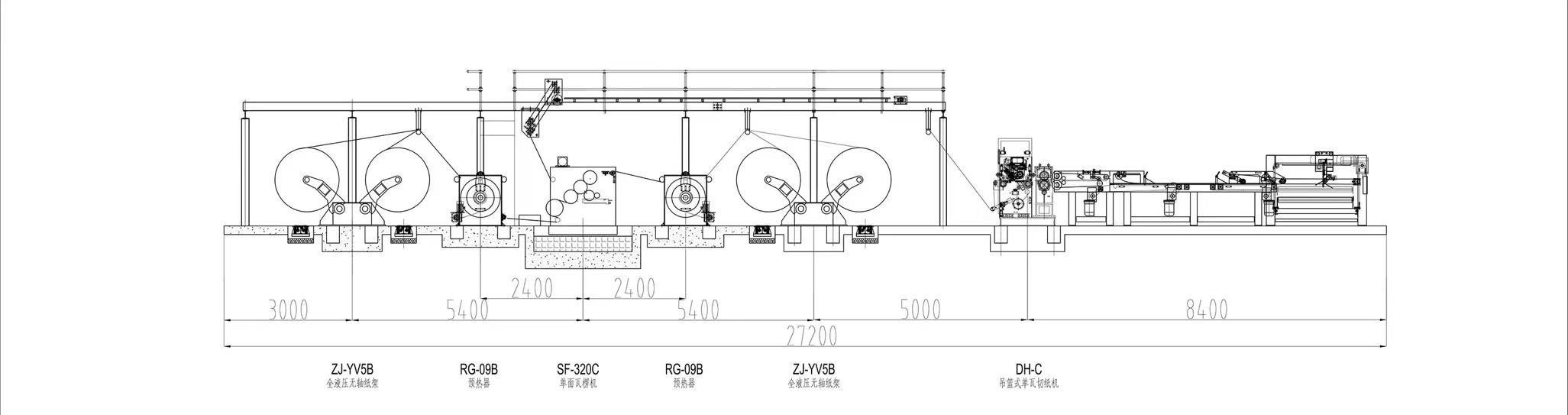

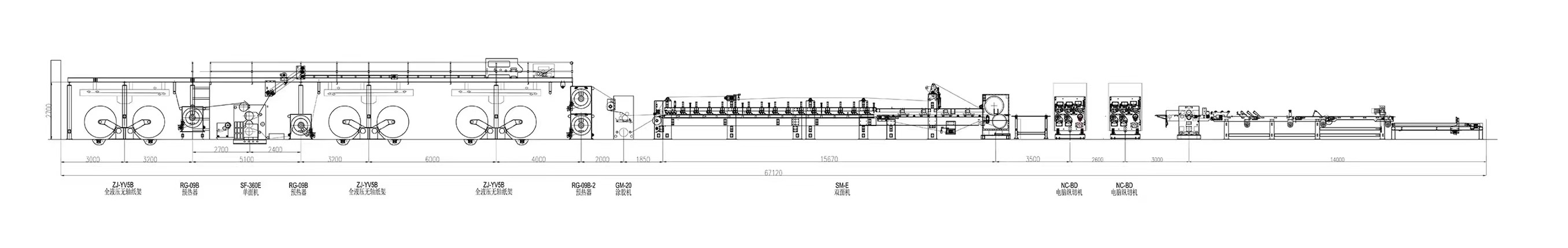

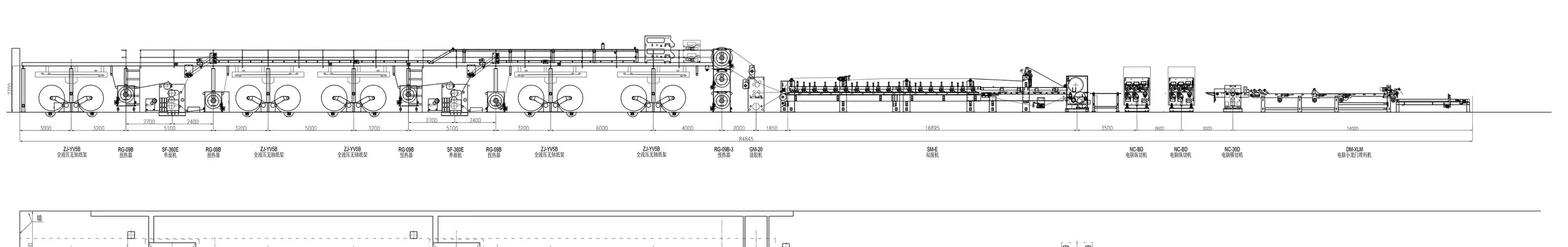

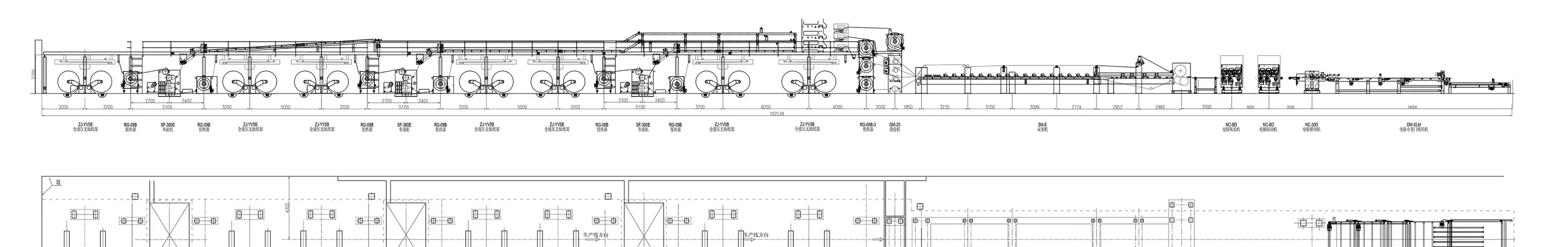

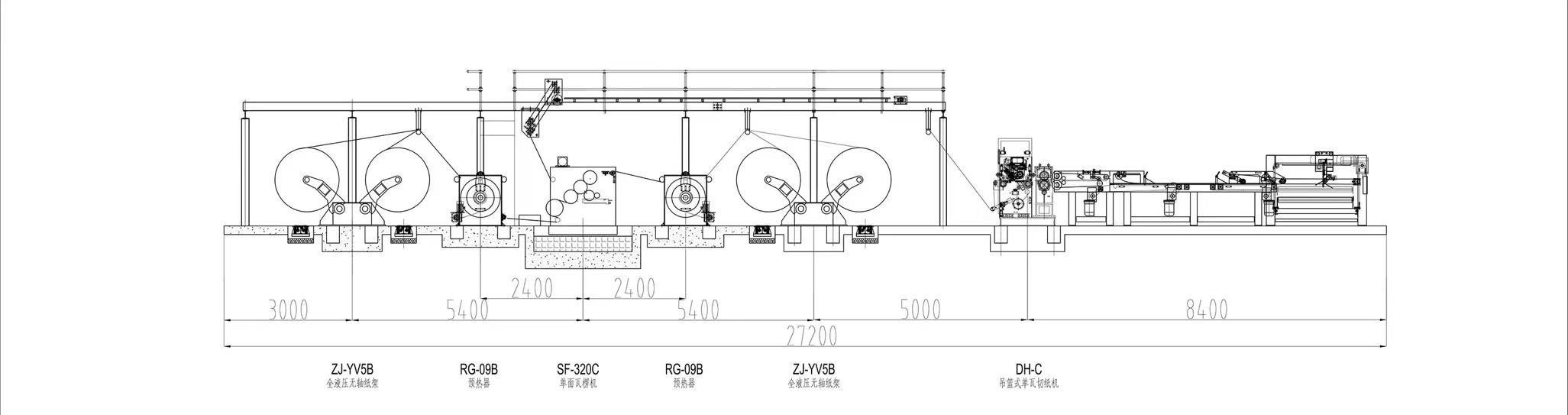

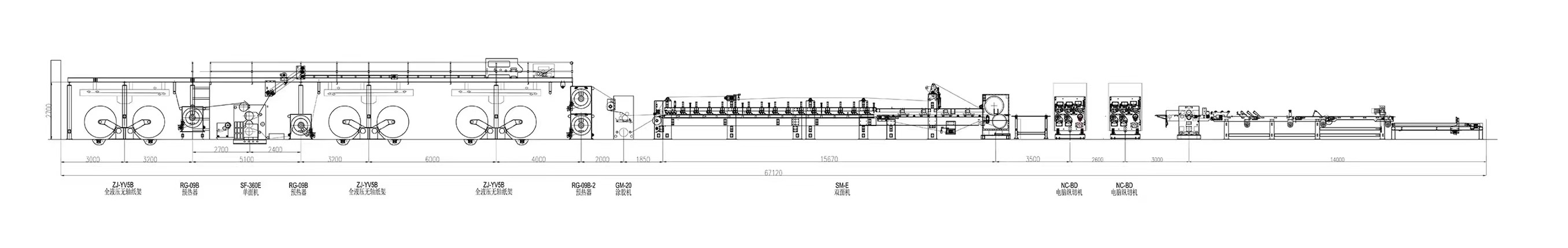

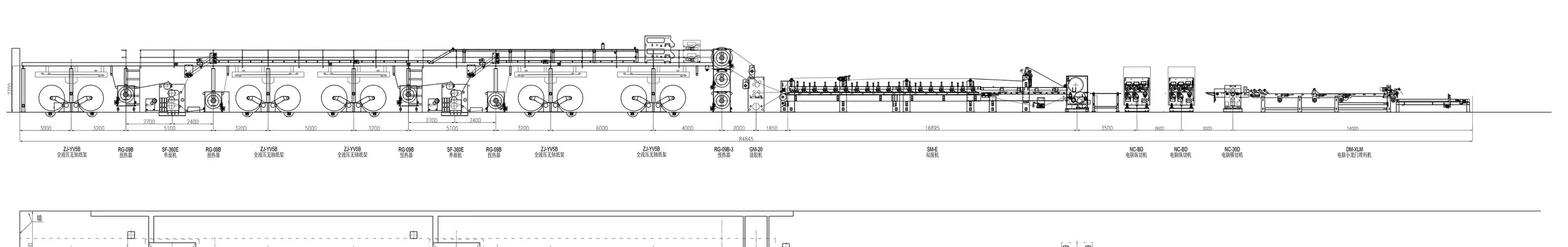

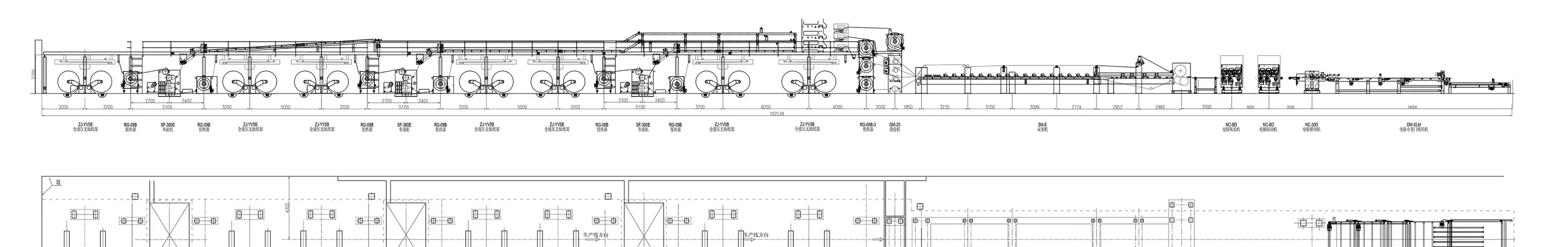

Plane Structure Drawing Of Production Line

Service

Quality control department are

specially responsible for quality in each process

We have been kept providing high quality products by introducing advanced technologies for over 20 years, and our products are also widely exported to many different

countries including Russia, the Middle East, Africa, Southeast Asia, EU, etc, which earned us a high reputation among the customers.

TM online for 24 hours, also contact by email, skype, MSN, whatsapp, etc.

To solve the problems with videos/pictures.

One year warranty for spare parts change.