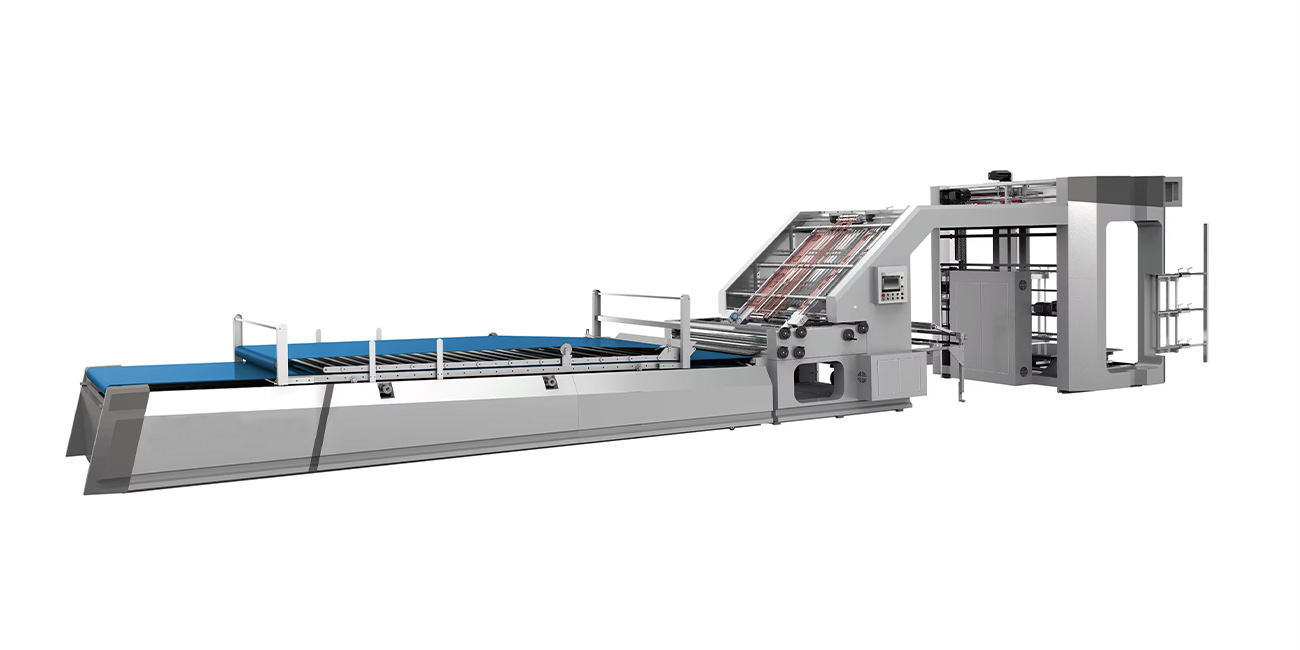

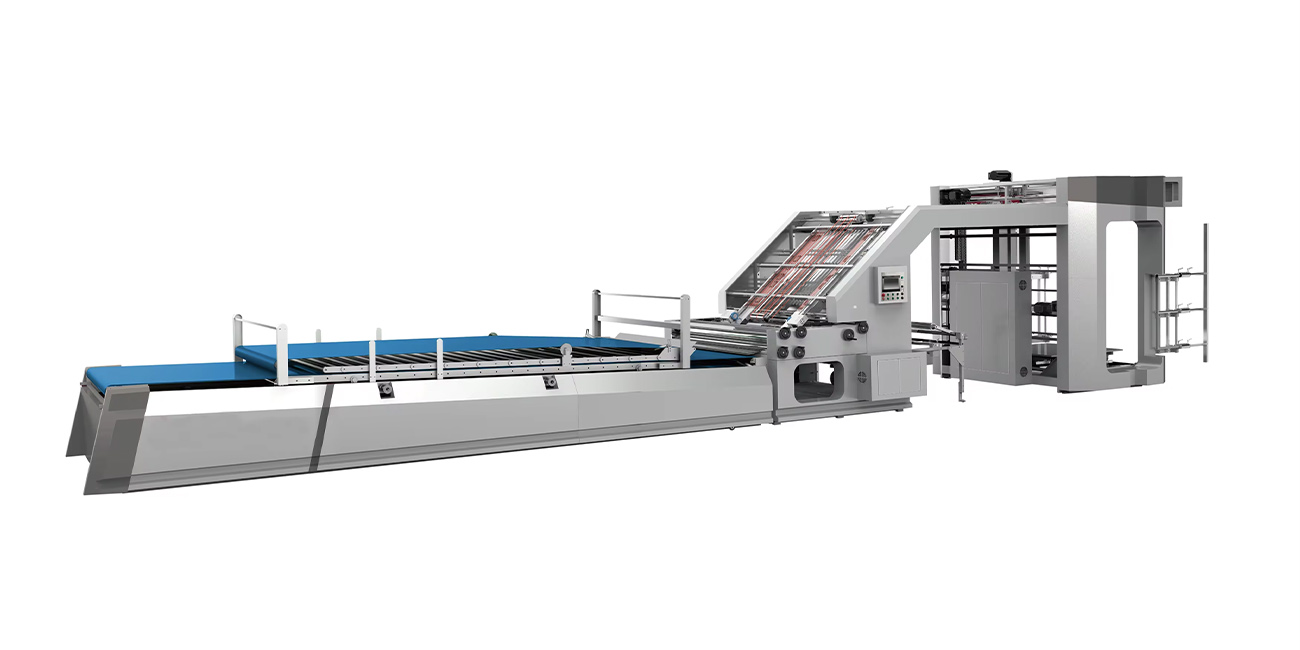

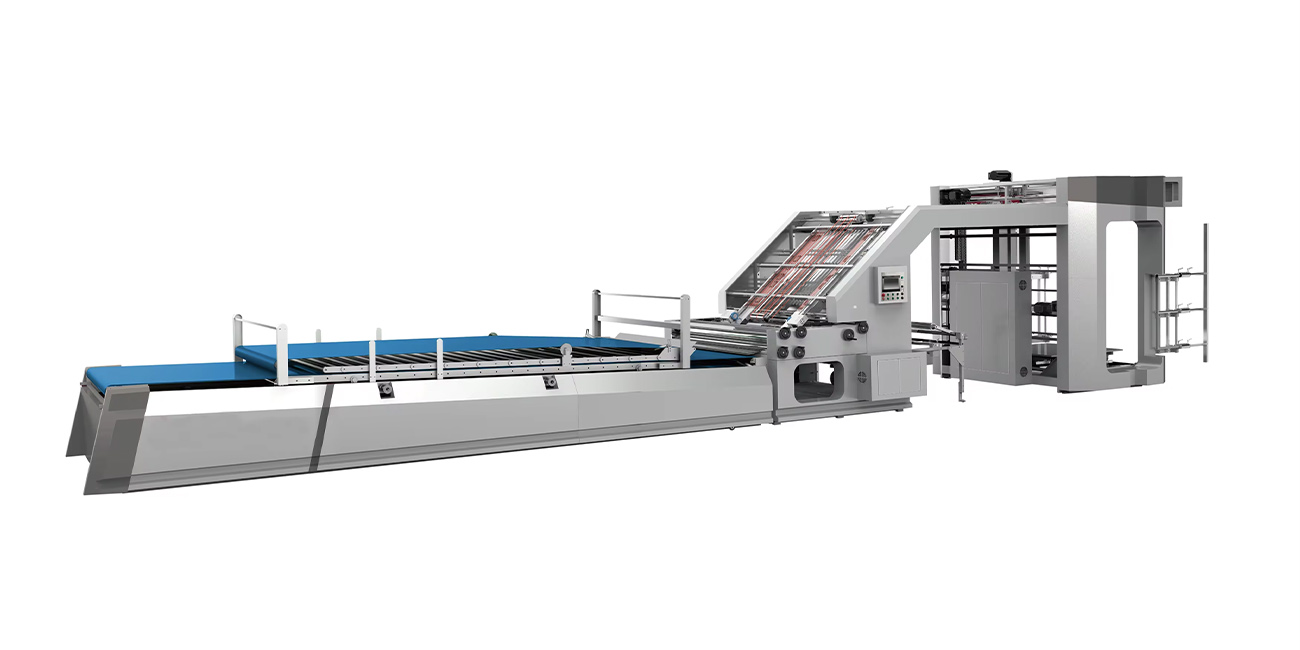

Product

Description

Main

features:

1. Computerized high speed lamination up to 150m/min. Depending on the quality of sheets.

2. E shape lifting board used for the feeding unit enables sheets to be pushed into position by hydraulic jack.Rail with pre-piling device are available for option.

3.High strength feeder ensures smooth running with no missing of sheet even at high speed.

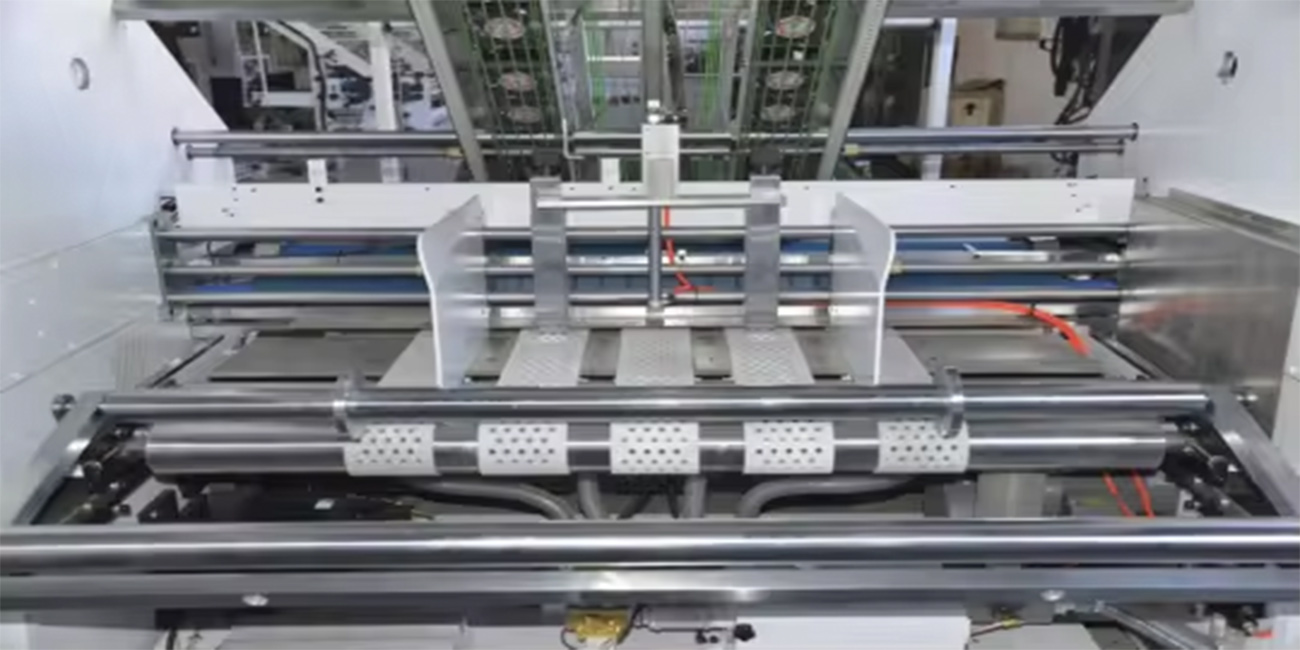

4.Sensing and compensation and alignment device uses several group of sensors to sense the relative position of the running corrugated board so that two servo motors at

left and right side of the top paper can drive independently to align top paper with corrugated paper with high accuracy and high speed.

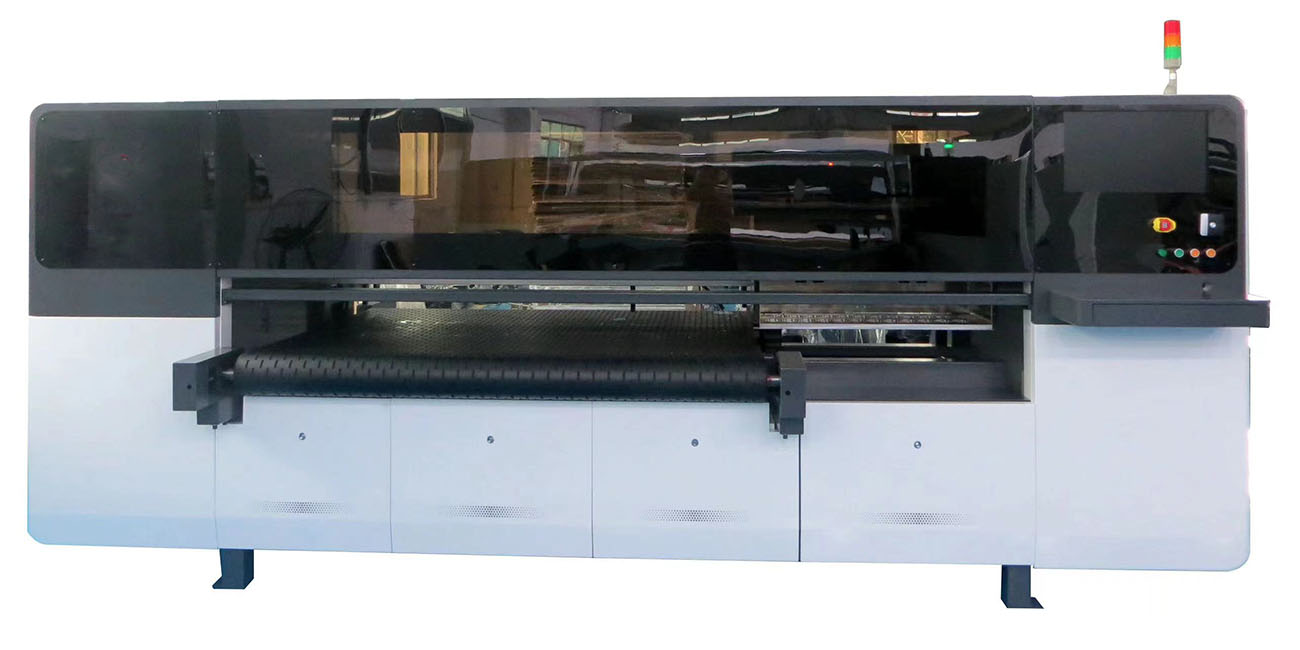

5.Global-functional electric control system with touch screen and PLC program monitors automatically the working condition and facilitate trouble shooting. The electric

design conforms to the CE standard.

6.Gluing unit uses high precise coating wheels, together with specially designed metering roller enhances the evenness of gluing.The unique gluing wheel with glue stopping

device and automatic glue level control system guarantees backflow with no overflow of glue.

7.Machine frames are processed by CNC lathe in one process, which ensures the precise of every positions. Toothed belts for transferring guarantees smooth running with low

noise. Motors and the spares uses Chinese famous brand with high efficiency, less trouble and long service life.

8.Corrugated board feeding unit adopts powerful servo motor control system with the features of high sensitivity and fast speed. The suction unit uses high-pressure

blower,SMC high- flow control valve as well as unique dust collection filter box, which enhances suction force for different corrugated paper, ensuring smooth running with

no double or more sheets, no missing sheet.

9.Automatic Glue Supply System: The machine adopts imported liquid level controller for glue supply. When glue is insufficient, it can stop the feeder automatically to

avoid waste of paper.

Product

Specifications:

|

Model

|

Unit

|

BZJ-1300S

|

BZJ-1450S

|

BZJ-1600S

|

|

Max.size

|

mm

|

1300✖️1100

|

1450✖️1100

|

1600✖️1100

|

|

Min.szie

|

mm

|

350✖️350

|

350✖️350

|

350✖️350

|

|

Laminate precision

|

mm

|

≤±1.5

|

≤±1.5

|

≤±1.5

|

|

Speed

|

m/min

|

100

|

100

|

100

|

|

Total power

|

KW

|

12

|

12

|

12

|

|

Length

|

M

|

12.5✖️2.15✖️2.6

|

12.5✖️2.30✖️2.6

|

12.5✖️2.45✖️2.6

|

|

Total weight

|

T

|

6.8

|

7.2

|

8.0

|

Service

Quality control department are

specially responsible for quality in each process

We have been kept providing high quality products by introducing advanced technologies for over 20 years, and our products are also widely exported to many different

countries including Russia, the Middle East, Africa, Southeast Asia, EU, etc, which earned us a high reputation among the customers.

TM online for 24 hours, also contact by email, skype, MSN, whatsapp, etc.

To solve the problems with videos/pictures.

One year warranty for spare parts change.