Product

Features

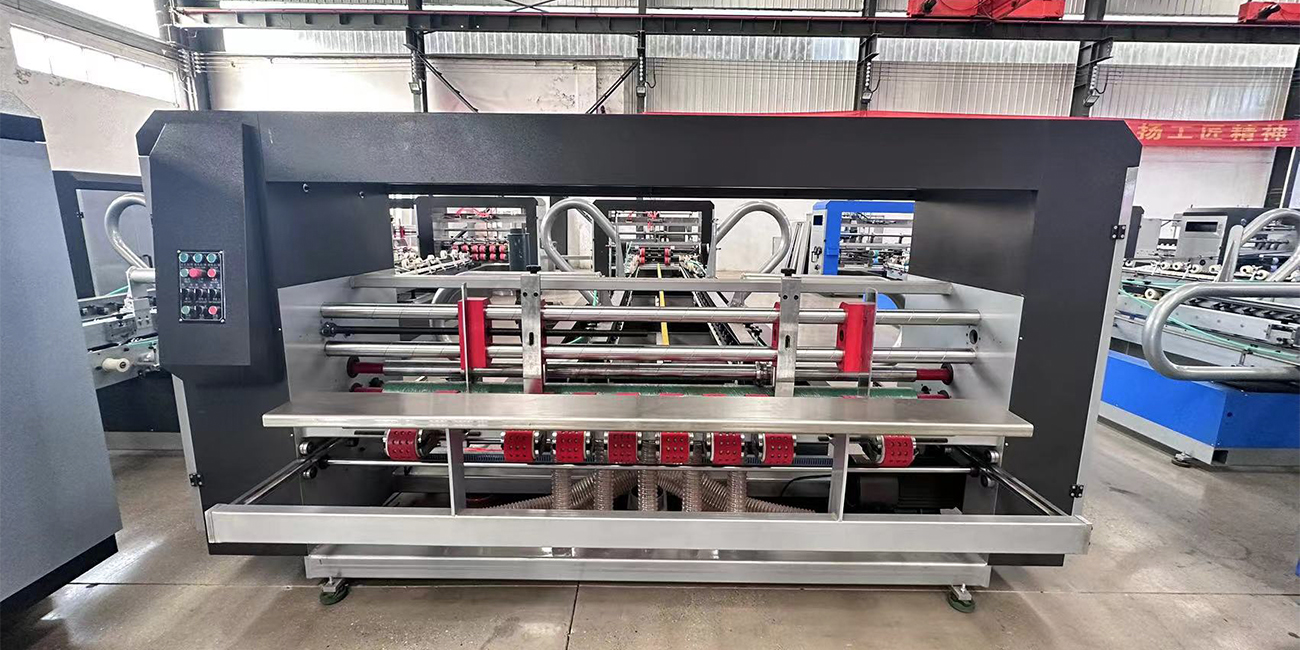

Automatic Stitching Machine is mainly designed to replace

the pure manual and semi-automatic box gluing and nail box machine. Solve the persistent problems of packaging companies in pasting boxes and nail box forming processes,

such as a large number of people, a large area, low efficiency, and poor quality. Our company has developed the full-automatic box-gluing and nail-box all-in-one machine.

This model has the advantages of high speed, high quality and high intelligence. Save a lot of skilled workers, save half of the glue, and achieve a double harvest of

efficiency and quality. Contribute to the development of packaging enterprises.

1. The paper feeding department

1) belt leading edge suction paper feeding method is adopted, which is accurate and reliable.

2) the use of high-grade electromagnetic clutch and electromagnetic brake system, so that the paper feeding part can be independently controlled, simple and reliable

operation.

3) the height of the line pressing wheel is adjustable, suitable for the cardboard thickness of 2-8mm.

4) linkage with folding part, frequency conversion speed control, paper supply speed 0-200pcs/min.

5) the front baffle of the paper feeding department and the paper belt are adjustable.

Gluing and folding section

1) the main motor adopts frequency conversion speed regulation system with no noise and stable speed regulation.

2) adopt imported high friction belt conveying paperboard, automatic folding.

3) stainless steel wheel coating, uniform amount of glue, no fault and save glue.

4) the folding part is equipped with a cardboard correction device and an indentation correction device.

5) the folding part has two rows of adjustable inner positioning regulating wheel system, with higher molding accuracy.

6) folding speed 0-200m/min.

Pre-folding Unit

Using patented technology Mitsubishi servo motor and timing belt to drive three clappers, to achieve the same paper correction device for chasing shots, minimize the

damage of the cardboard, perform secondary compensation and correct the phenomenon of not in place, eliminate the scissors mouth, and make the nail box more perfect. Main

motor Japan Mitsubishi servo motor. The paper conveying belt adopts the famous domestic brand belt. The servo motor drives the clapper through the timing belt to realize

the alignment of the carton, making it easier to accurately control the clapper.

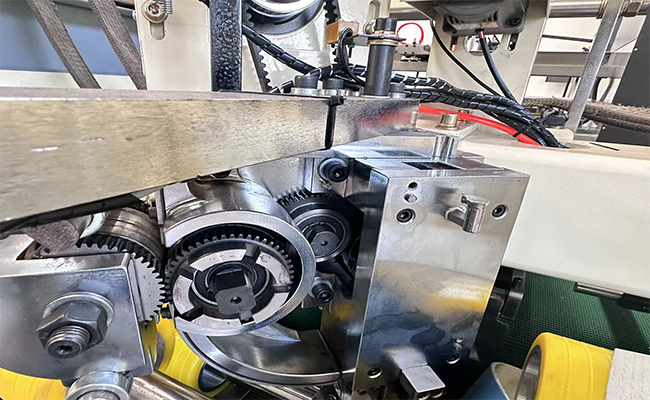

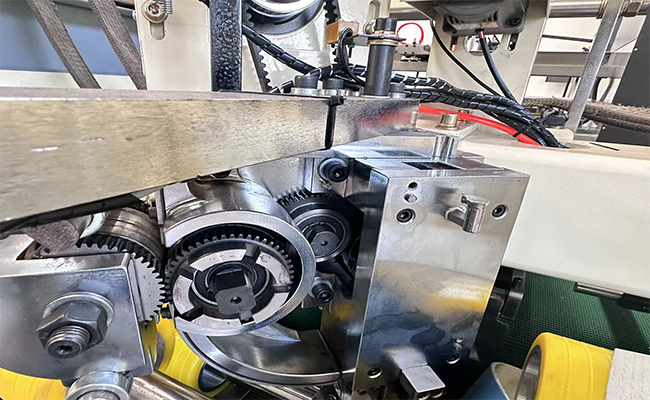

Stitching Unit

1.Using synchronous belt conveyor, PLC control, touch screen adjustment, (such as: nail box page, glue box page: used for nail box, glue box exchange: stage display: nail

box speed and work output can be viewed when nailing the box. ) Convenient, fast and accurate.

2.It has a flapping correction device to compensate and correct the lack of position of the box piece, effectively reducing the occurrence of scissors.

3.Adopt swing nail head to effectively improve the quality of nail box.

4.Adopt standard 17#(2.0*0.7mm) 18#(1.81*0.71mm) nail wire, size tolerance: +0.02mm, reliable quality 20kg wire reel, reduce the number of wire changes and improve

production efficiency.

5.With order memory function, it can effectively reduce the time of order change adjustment and improve production efficiency.

6.Nailing speed 1200 nails/minNail angle 45 degreesNail distance range 30-120mm

Counting&Delivery Unit

1.After the glued carton is finished, it will be patted, counted, stacked again and sent out automatically.

2.With differential correction, the accumulation speed is 130m/min.

3.Pneumatic method is adopted for counting and pushing out, which is reliable, accurate and fast.

4.Equipped with an emergency stop switch to avoid waste of cardboard in emergency situations and for safety design.

Electric Control Unit

1.Use touch screen to input various carton data, complete specification adjustment and order change, simple operation and reliable action.

2.It can input data without stopping the machine, automatically count and output accurately.

3.Total installed capacity: 30KW The electric control system adopts the latest PLC computer automatic control system of Japan's Mitsubishi, from gluing, folding,

sorting, staple box, paper delivery, automatic detection and control, and Japan Fuji contactor. The man-machine interface display system can display various working

conditions, point out where the fault occurred and propose solutions. Equipped with a variety of safety protection devices, sound and light alarms when failure occurs, and

automatically shut down to ensure the safety of man and machine.

Service

Quality control department are

specially responsible for quality in each process

We have been kept providing high quality products by introducing advanced technologies for over 20 years, and our products are also widely exported to many different

countries including Russia, the Middle East, Africa, Southeast Asia, EU, etc, which earned us a high reputation among the customers.

TM online for 24 hours, also contact by email, skype, MSN, whatsapp, etc.

To solve the problems with videos/pictures.

One year warranty for spare parts change.